2021 High quality Bag Filter Solenoid Valve - Y JD series Star Unloader – Xintian

2021 High quality Bag Filter Solenoid Valve - Y JD series Star Unloader – Xintian Detail:

YJD-A/B series unloading device, also known as electric ash unloading valve and electric lock valve, consists of three parts: motor, tooth difference planetary reducer (X) or pinwheel cycloid reducer (Z) and rotary unloader. There are two series and 60 specifications

The square flanges of import and export are type A, and the circular flanges are type B

The device is a dust removal equipment, the main equipment for conveying, discharging ash, locking air and other equipment feeding. It is suitable for powder and granular materials. Installation size is consistent with all kinds of dust collectors, which is widely used in environmental protection, mining, metallurgy, chemical industry, grain, chemical and other industrial sectors

Special motors, such as explosion-proof, frequency modulation, speed regulation and marine motors, can be configured according to needs of users in order to meet users’special requirements. The material can also be processed according to the needs of users, such as high humidity resistance, corrosion resistance, stainless steel, flexible blades, explosion-proof impellers, etc

Technical parameters of A/B-X/Z YJD unloader:

|

Model Name Data |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

YJD |

|

|

Unloader L/r |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

26 |

30 |

|

|

Unloader m³/h |

4.08 |

8.16 |

12.24 |

16.32 |

20.4 |

24.48 |

28.56 |

36.64 |

36.72 |

40.8 |

50.64 |

61.2 |

|

|

Inner diameter mm |

150 |

180 |

200 |

220 |

240 |

260 |

280 |

300 |

320 |

340 |

400 |

440 |

|

|

r/min |

Type Z |

25-40(standard speed:34r/min) |

|||||||||||

|

Working temperature °C |

T ≤80°C T ≤200°C |

||||||||||||

|

Materiel |

Powdery, granular |

||||||||||||

|

Electric machinery |

Model |

Y801 |

Y802-4 |

Y90S-4 |

Y90L-4 |

Y100L1-4 |

Y100L2-4 |

||||||

|

KW |

0.55 |

0.75 |

1.1 |

1.5 |

2.2 |

3 |

|||||||

|

r/min |

1390 |

1400 |

1430 |

||||||||||

|

Weight kg |

53 |

71 |

86 |

101 |

121 |

141 |

161 |

181 |

191 |

221 |

251 |

301 |

|

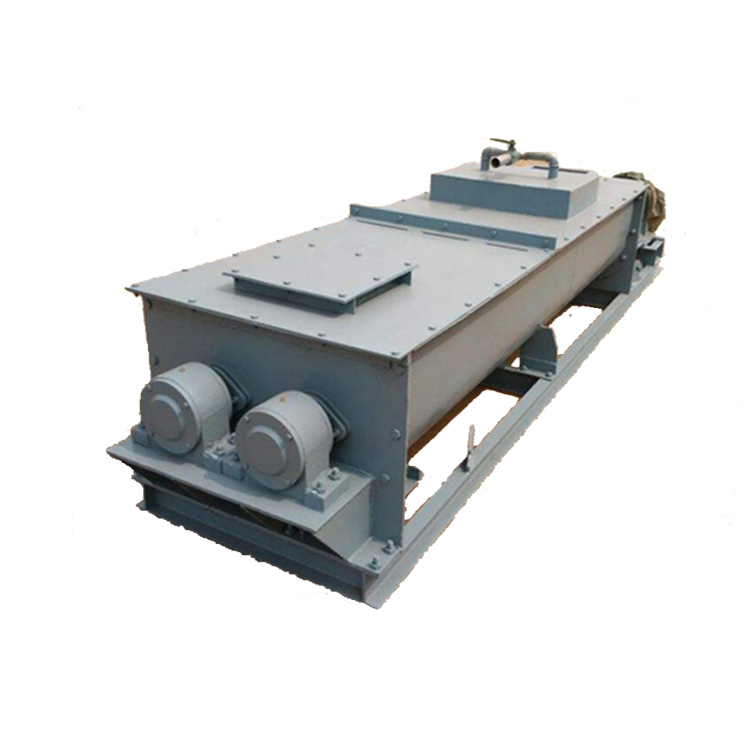

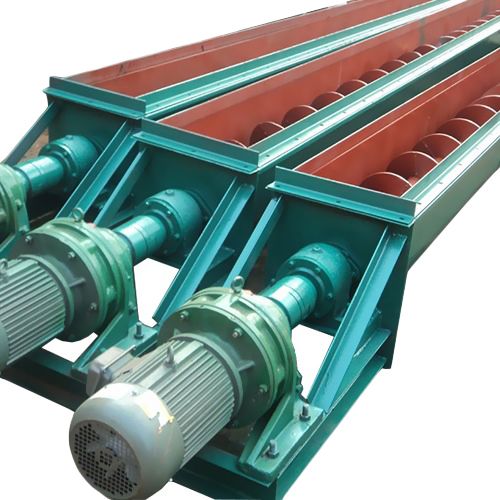

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency profits team values customers' requirements and organization communication for 2021 High quality Bag Filter Solenoid Valve - Y JD series Star Unloader – Xintian , The product will supply to all over the world, such as: Turkmenistan, Paris, Cape Town, Customer's satisfaction is always our quest, creating value for customers is always our duty, a long term mutual-beneficial business relationship is what we are doing for. We are an absolutely reliable partner for you in China. Of course, other services, like consulting, can be offered too.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.