Discountable price Smoke Precipitator - Esp Wet Electrostatic Precipitator For Boiler Flue Gas Desulfurization – Xintian

Discountable price Smoke Precipitator - Esp Wet Electrostatic Precipitator For Boiler Flue Gas Desulfurization – Xintian Detail:

Product Description

The wet electrostatic precipitator uses the method of electrostatic precipitator to separate the aerosol and suspended dust particles in the gas. It mainly includes the following four complex and interrelated physical processes:

(1) Ionization of gas. Dust Collector Equipment.

(2) Condensation and charging of aerosols and suspended dust particles.

(3) The charged dust particles and aerosol move to the electrode.

(4) The water film makes the electrode plate clean.

Tens of thousands of volts of DC high voltage is applied between the anode and cathode wires of the wet electrostatic precipitator. Under the action of a strong electric field, a corona layer is generated around the corona wire, and the air in the corona layer undergoes avalanche ionization, thereby producing A large number of negative ions and a small amount of positive ions, this process is called corona discharge; the dust (fog) particles that enter the wet electrostatic precipitator with the flue gas collide with these positive and negative ions to be charged, and the charged dust (fog) Due to the Coulomb force of the high-voltage electrostatic field, the particles move toward the anode; after reaching the anode, the charge is released, and the dust (fog) particles are collected by the anode, and the dust is collected to form a water film, which is self-cleaning by gravity or washing. It flows up to the lower liquid accumulation tank or absorption tower, and is separated from the flue gas.

Working principle

When the gas containing tar droplets and other impurities passes through the electric field, the impurities of negative ions and electrons are adsorbed, under the action of coulomb force of electric field, and then the charge is released after moving to precipitating pole, and adsorbed on the precipitating pole, so as to achieve the purpose of purifying the gas, which commonly known as the charge phenomenon. When the impurity mass adsorbed on the precipitating pole increases to greater than its adhesion, it will automatically flow down and discharge from the bottom of electric tar catcher, and the net gas will leave from the upper part of electric tar catcher and enter into the next process,ESP dust collector.

Specification

| item | value |

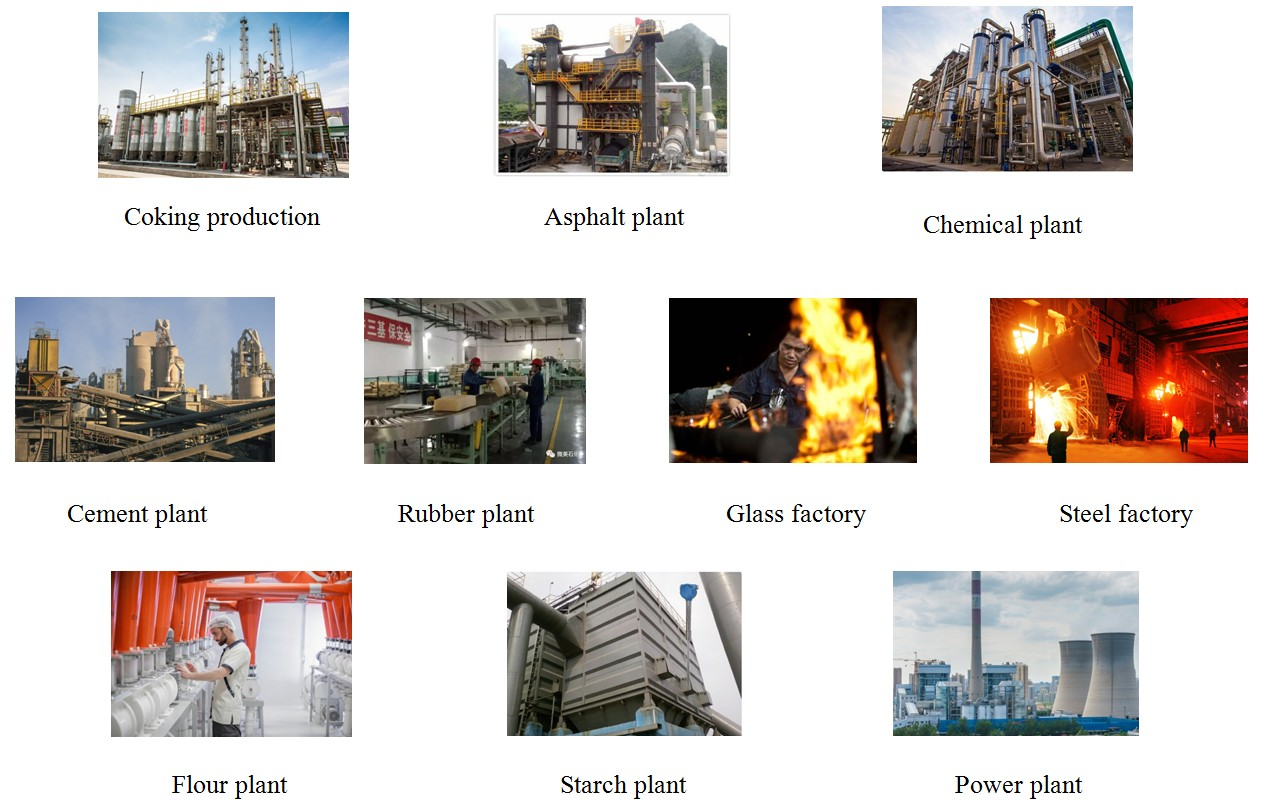

| Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Energy & Mining, Cement plant, Power plant, Chemical plant, Metallurgical plant, Mining company, Pharmaceutical factory, Building Material Factory, Rubber factory, Machinery Plant, Boiler plant, Flour mill, Furniture Factory, Glass factory, Asphalt plant |

| After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location | None |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | Ordinary Product |

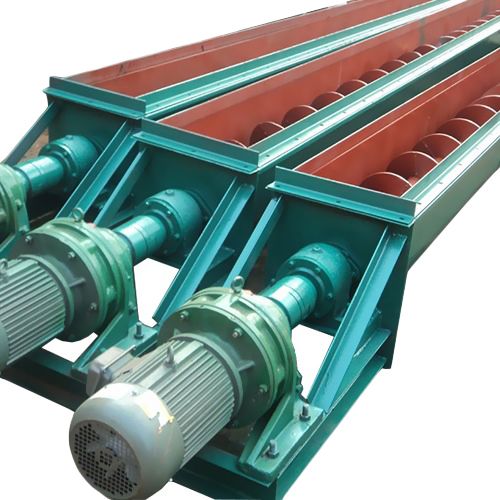

| Core Components | PLC, Engine, Motor, Filter Bag, Blower, Filter Cage, Dust Unloading Valve, Bucket Elevator, Screw Conveyor, Pulse Valve |

| Condition | New |

| Minimum Particle Size | 0.5mm |

| Place of Origin | China |

| Hebei | |

| Brand Name | SRD |

| Dimension(L*W*H) | Customized |

| Weight | 1200kgs-3200kgs |

| Certification | CE SGS ISO Certificate |

| Warranty | 3 years |

| After-sales Service Provided | Free spare parts |

| Product name | Bag Filter Dust Collector Machine |

| Usage | Filter Industry Dust |

| Material | Carbon Steel |

| Power | 2.2kw-90kw |

| Cleaning way | Auto Pulse Jet Cleaning System |

| Dust collection type | Industral Dust Collector |

| Color | Customers’ Requirements |

| Air volume | 5000 – 120200m3 |

| FILTER AREA | 96 – 1728 M2 |

| Air flow | 12000-70000m3/h |

Application Scope: This product is mainly used for chemical fertilizer, coking, gas, carbon, metallurgy, building materials, ceramics and other industries of gas purification, used to recover gas, tar in coke oven gas, while removing dust, water fog and other impurities, to achieve the dual effects of material recovery and gas purification.

Packaging and Shipping

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Discountable price Smoke Precipitator - Esp Wet Electrostatic Precipitator For Boiler Flue Gas Desulfurization – Xintian , The product will supply to all over the world, such as: Karachi, Czech republic, Singapore, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!