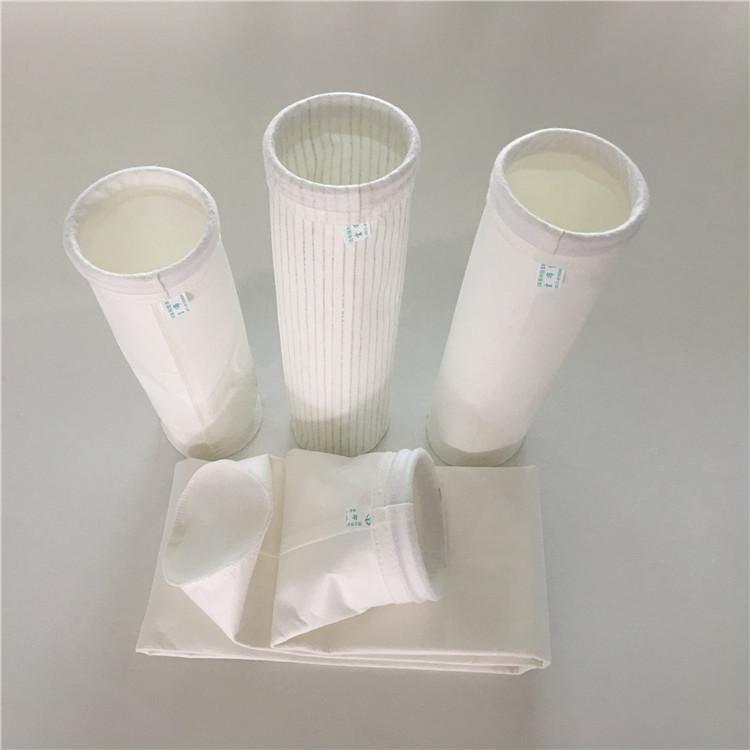

Factory best selling Turbo Pulse Valves - Three-proof Polyester Needle-punched Felt Bag (waterproof, antistatic, oil-proof) – Xintian

Factory best selling Turbo Pulse Valves - Three-proof Polyester Needle-punched Felt Bag (waterproof, antistatic, oil-proof) – Xintian Detail:

In the process of producing needle-punched felt,conductive fibers or conductive materials are mixed into chemical fibers. The filter cloth is rolled and imegnated with PTFE (waterproof agent),which is used in occasions with high moisture content .The filter material is not easy to block the paste bag,the service life of the cloth bag is prolonged,the gas flow rate is increased, and the maintenance cost is greatly saved.

The bag has the advantages of high void, good air permeability, high dust collecting efficiency and long service life, which are peculiar to common felt filter bags. It has moderate high temperature resistance, and can reach 130″C in an instant. It also has moderate acid and alkali resistance. and very good wear resistance.

| Weight | 500/m2 |

| Material | Polyester/Polyester Antistatic Substrate |

| Thickness | 1.8mm |

| Permeability | 11m3/m2.min |

| Radial control force | >1100N/5*20cm |

| Latitudinal control force | > 1300N/5 x 20cm |

| Radial control force | <35% |

| Latitudinal control force | <45% |

| Usage temperatures≤ | 130°C |

| Post-treatment | singeing, calendering or Teflon coating |

Product detail pictures:

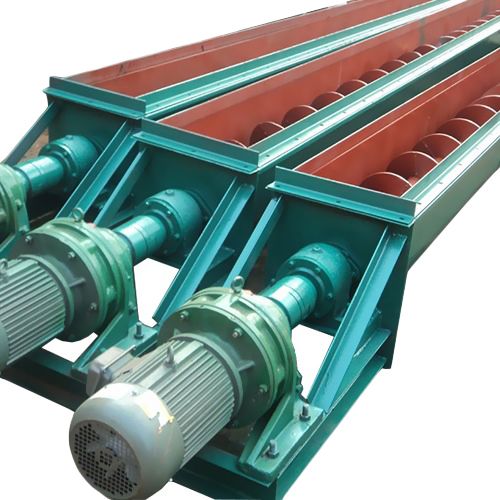

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Factory best selling Turbo Pulse Valves - Three-proof Polyester Needle-punched Felt Bag (waterproof, antistatic, oil-proof) – Xintian , The product will supply to all over the world, such as: Denmark, Bahamas, Guatemala, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us