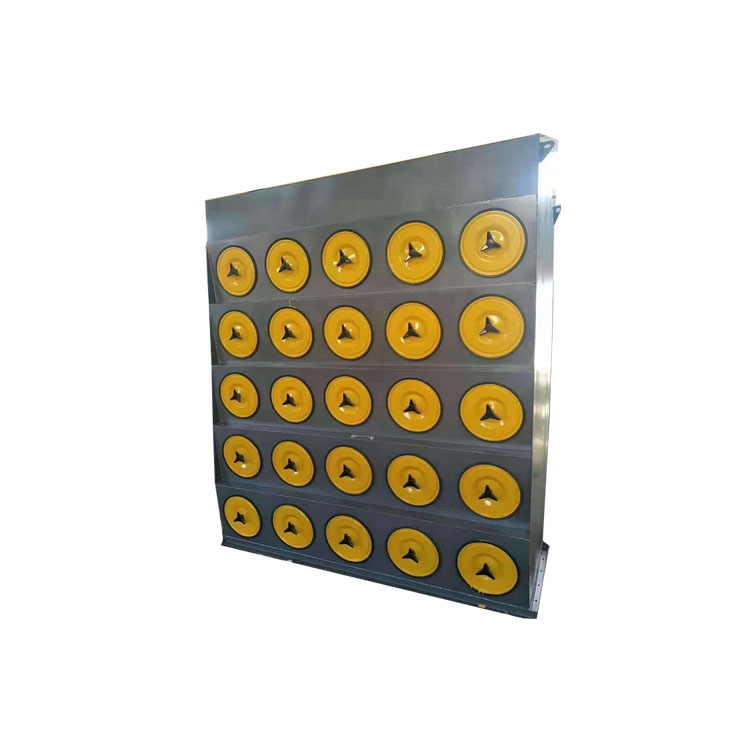

Factory Outlets 24 Diameter Dust Collector Bags - HMC series pulse cloth bag dust collector – Xintian

Factory Outlets 24 Diameter Dust Collector Bags - HMC series pulse cloth bag dust collector – Xintian Detail:

HMC series pulse cloth bag dust collector is a single type bag dust collector. It adopts circular filter bag, self-contained air ventilation system with pulse injection ash cleaning mode, which has advantages of high dust removal efficiency, good ash cleaning effect, low operation resistance, long service life of filter bag, simple maintenance and stable operation, etc.

When the dust gas enters into the cloth bag dust collector from air induced system, due to the decrease of wind speed, the dust particles with a large proportion settle into the ash hopper, and the lighter dust depends on the air induction to reach the surface of dust removal filter bag. The filter bag of dust collector generally uses needle felt as the filter carrier, and the filtration accuracy can reach <1um. The dust is blocked on the surface by the filter bag, and the dust gas is purified through the filter bag. With the increasing of time, more and more dust is filtered on the surface of filter bag, so the resistance of the filter bag is gradually increased. In order to make the dust collector work normally, when the resistance rises to a limited range, the electronic pulse controller issues instructions to follow the order. The sequence triggers each control valve to open the pulse valve, and the compressed air in the gas storage bag of dust collector is sprayed into the corresponding filter bag by each injection hole of the injection pipe. The filter bag expands rapidly under the instantaneous reverse action of air flow, which makes the dust attached to the surface of the filter bag fall off and makes the filter bag achieve the most original air permeability filtration effect. The cleared dust falls into the ash hopper and drains out of the body through the ash removal system to complete the whole ash cleaning and filtration process.

Technical Parameters of Equipment Selection:

|

Equipment Model |

HMC-24 |

HMC-32 |

HMC-36 |

HMC-48 |

HMC-64 |

HMC-80 |

|

|

Total Filtration Area m² |

20 |

25 |

30 |

40 |

50 |

64 |

|

|

Filtration Velocity m³/min |

1.0-2.0 |

||||||

|

Air Volume m³/h |

1200-2400 |

1500-3000 |

1800-3600 |

2400-4800 |

3000-6000 |

3840-7680 |

|

|

Quantity of Filter Bag |

24 |

32 |

36 |

48 |

64 |

80 |

|

|

Specification and Material of Filter Bag |

130*2000mm |

||||||

|

Air Outlet Dust Concentration mg/m³ |

≤30 |

||||||

|

Beard Negative Pressure Pa |

5000 |

||||||

|

Equipment Running Resistance Pa |

800-1200 |

||||||

|

Injection Pressure Mpa |

0.4-0.6 |

||||||

|

Electromagnetic |

Specification |

DMF-Z-25(G1″) |

|||||

|

Quantity |

4 |

4 |

6 |

6 |

8 |

8 |

|

|

Induced Draft Fan Model |

4-72-2.8A |

4-72-3.2A |

4-72-3.6A |

4-72-3.6A |

4-72-4A |

4-72-4.5A |

|

|

Power of Motor |

1.5kw |

2.20kw |

3kw |

4kw |

5.5kw |

7.5kw |

|

Equipment Model: HMC- 160B Pulse Cloth Bag Dust Collector

Application Field: Dust removal of combined grinder, grooving machine, grinding and cutting machine.

|

Equipment Model |

HMC-96 |

HMC-100 |

HMC-120 |

HMC-160 |

HMC-200 |

HMC-240 |

|

|

Total Filtration Area m² |

77 |

80 |

96 |

128 |

160 |

192 |

|

|

Filtration Velocity m³/min |

1.0-2.0 |

||||||

|

Air Volume m³/h |

4620-9240 |

4800-9600 |

5760-11520 |

7680-15360 |

9600-19200 |

11520-23040 |

|

|

Quantity of Filter Bag |

96 |

100 |

120 |

160 |

200 |

240 |

|

|

Specification and Material of Filter Bag |

130*2000mm |

||||||

|

Air Outlet Dust Concentration mg/m³ |

≤30 |

||||||

|

Beard Negative Pressure Pa |

5000 |

||||||

|

Equipment Running Resistance Pa |

800-1200 |

||||||

|

Injection Pressure Mpa |

0.4-0.6 |

||||||

|

Electromagnetic |

Specification |

DMF-Z-25(G1″) |

|||||

|

Quantity |

12 |

10 |

12 |

16 |

20 |

20 |

|

|

Induced Draft Fan Model |

4-72-4.5A |

4-72-4.5A |

4-72-5A |

4-72-5A |

4-68-8C |

4-68-6.3C |

|

|

Power of Motor |

7.5kw |

7.5kw |

11kw |

15kw |

18.5kw |

22kw |

|

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Factory Outlets 24 Diameter Dust Collector Bags - HMC series pulse cloth bag dust collector – Xintian , The product will supply to all over the world, such as: Hamburg, Boston, Albania, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.