High definition Cement Dust Collection Systems - Desulphurization dust collector – Xintian

High definition Cement Dust Collection Systems - Desulphurization dust collector – Xintian Detail:

Desulphurization dust collector is a kind of cavitation liquid layer in which the flue gas to be treated in wind energy collecting cavitation room is collided with the desulphurization liquid at the upper end and bottom flow, and the gasliquid two phases collide and cut each other in the form of microbubble mass transfer, and the cavitation liquid layer with the impurity of the arrested set thickens gradually. Part of the breakthrough smoke buoyancy falls to the bottom of the tower, and the purified smoke rises from the chimney.

The desulphurization rate is higher than 95%, and the outlet concentration of smoke is less than 50mg / Nm3 .

There is no nozzle, which has no blockage, scaling and other problems .

The liquid-gas ratio is low, only about 20% of the air tower spray .

The failure rate is very low, as long as the induced draft fan and the liquid supply pump are normal, the device can operate stably and the operation is very simple.

The consumption of wind pressure is only 1200 – 1500 Pa .

After treatment, the flue gas does not contain foggy water droplets .

Low operating cost and investment .

The limestone slurry, lime slurry, alkali liquor, waste water of alkali liquor and the like can be used as the desulfurizing agent.

For high concentration, it is difficult to deal with the standard flue gas by general method. The flue gas with contents of S02 higher than 10000mg/Nm3 can be purified below 100mg/Nm3.

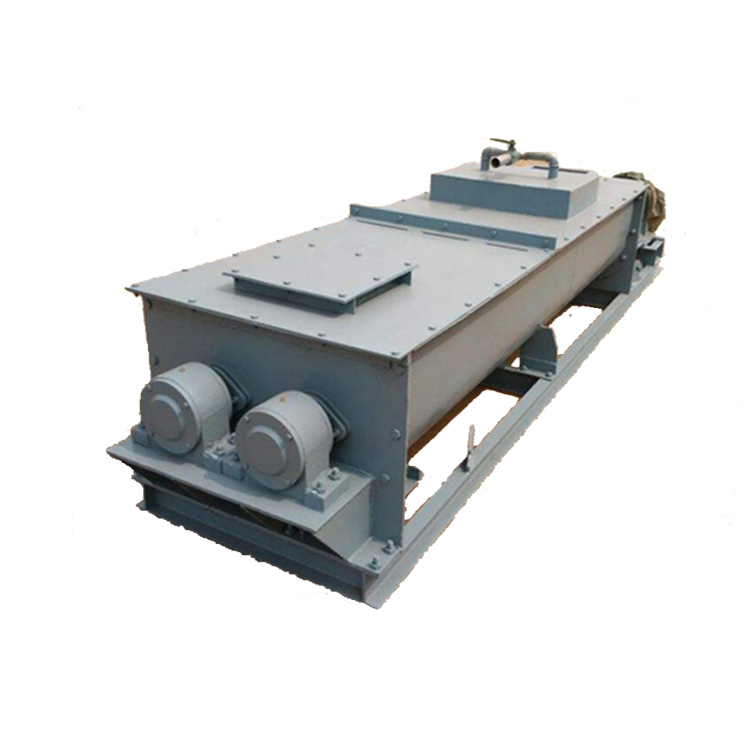

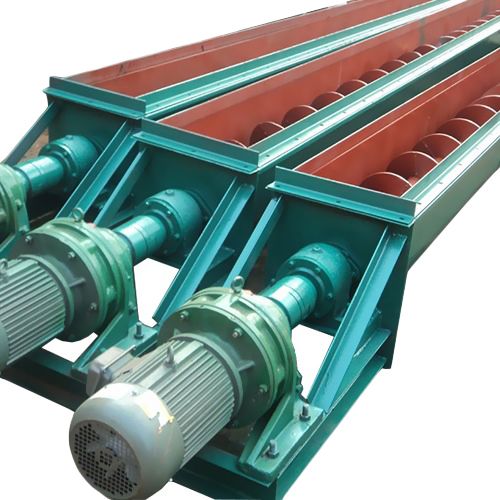

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for High definition Cement Dust Collection Systems - Desulphurization dust collector – Xintian , The product will supply to all over the world, such as: Kenya, Jersey, Dominica, We are proud to supply our products to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!