OEM Factory for Large Dust Collector - Bag filter dust collector for carbon plant – Xintian

OEM Factory for Large Dust Collector - Bag filter dust collector for carbon plant – Xintian Detail:

Product Description

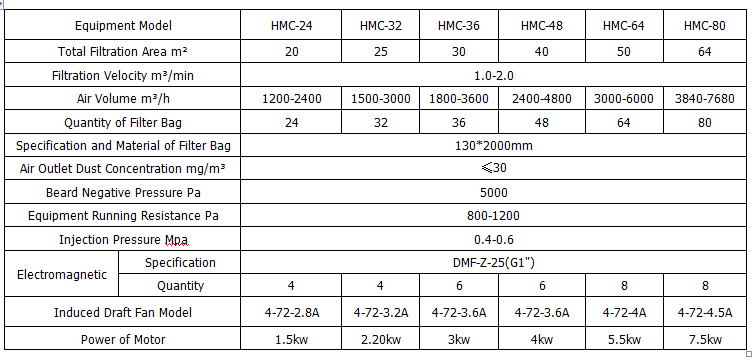

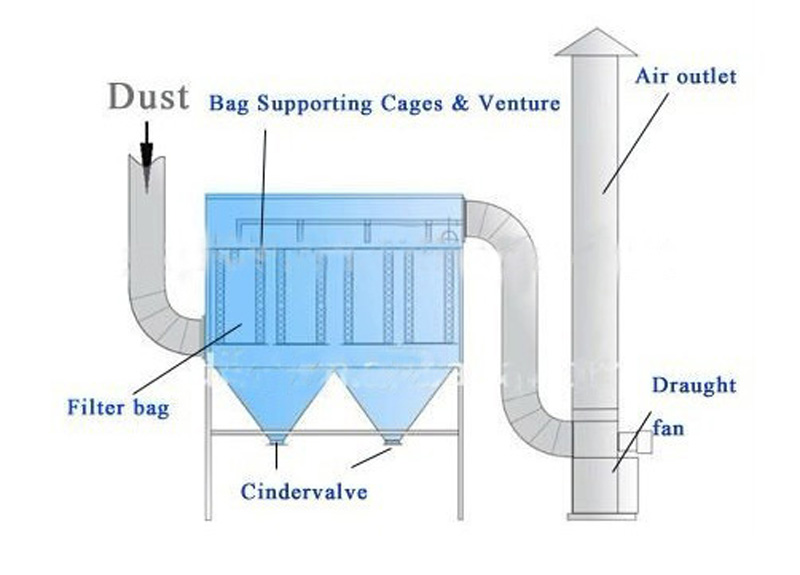

Dust collector is a system for filtering dust in flue gas/gas. Mainly used for the purification and recovery of dusty gas. The shell of the air pulse jet bag filter is an outdoor type, consisting of a shell, a chamber, an ash hopper, a discharge system, an injection system and an automatic control system. According to different combinations, there are many different specifications, air filter room and indoor air filter bag. There are four series of bags: 32, 64, 96, 128, with a total of 33 full series specifications; the filter bag parameters are 130mm in diameter and 2500mm in length; this series of dust collectors are operated under negative pressure, and the dust removal efficiency can reach more than 99.9%. After purification The dust emission concentration of the gas is 10-50mg/Nm³.

Technical Parameters of Equipment Selection:

Technical Parameters of Equipment Selection:

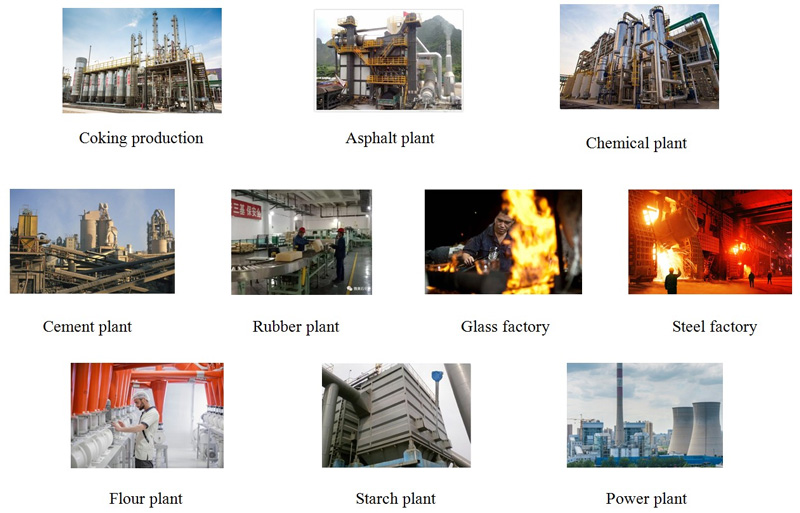

Application

Packing & Shipping

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for OEM Factory for Large Dust Collector - Bag filter dust collector for carbon plant – Xintian , The product will supply to all over the world, such as: Iran, Romania, Albania, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.