professional factory for Pulse Valve - High-temperature PPS Needle-punched Filter Felt Bag – Xintian

professional factory for Pulse Valve - High-temperature PPS Needle-punched Filter Felt Bag – Xintian Detail:

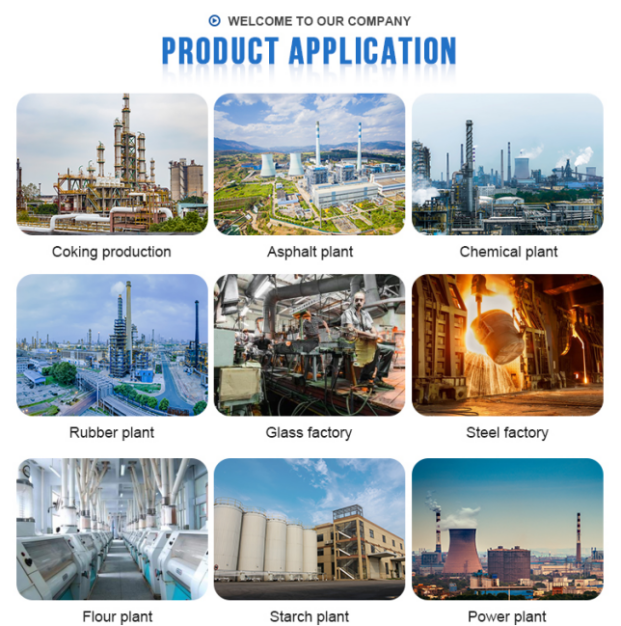

Beauty, dust bag with resistance to high temperature (204 ~ 240 ℃), strong acid, alkali, high filtering speed, low pressure loss, and the characteristics of the folding, good resistance to wear, but is not in the heat resistance to hydrolysis, mainly used in the asphalt mixing station flue gas, steel blast furnace gas, flue gas, carbon black (white carbon black) exhaust, cement kiln kiln kiln head, at high temperature furnace flue gas, Firebrick furnace smoke and coking smoke and other working conditions.

PSS fibers have complete strength retention and inherent chemical resistance, which can maintain good filtration performance in harsh environments and achieve ideal service life It is used to filter coal-fired boilers, garbage incinerators, dust collecting treatment of fly ash in power plants and pulse cleaning dust collectors.

Weight 500g/ m²

Material PSS Filament Substrate

Thickness 1 8mm

Permeability 15 m³/ m²· min

Radial control force > 1200N/5 x 20cm

Latitudinal control force > 1300N/S x 20cm

Radial control force <30%

Latitudinal control force. <30%

Usage temperature ≤ 190°C

Post-treatment high temperature hot pressing and singeing

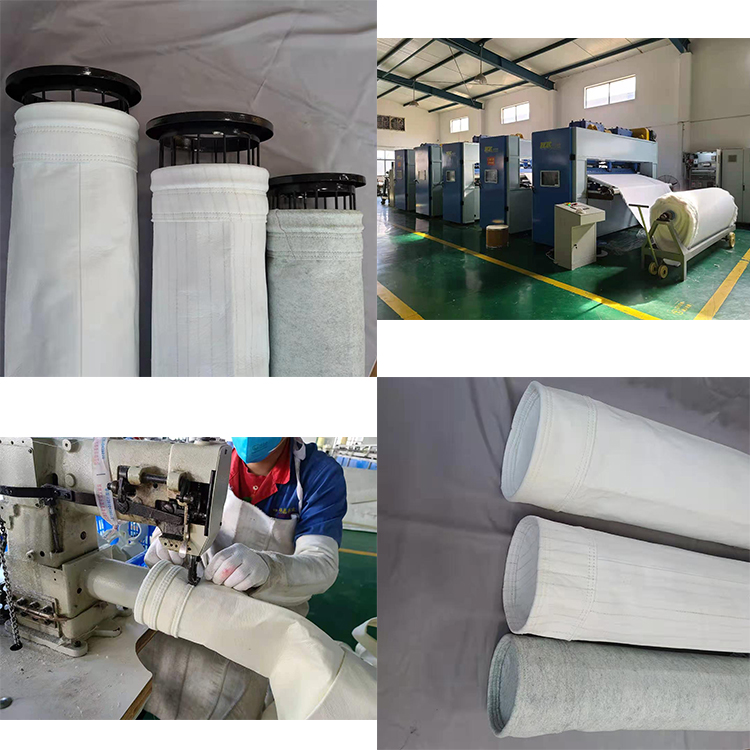

Product detail pictures:

Related Product Guide:

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for professional factory for Pulse Valve - High-temperature PPS Needle-punched Filter Felt Bag – Xintian , The product will supply to all over the world, such as: Swaziland, South Africa, Irish, Over the years, with high-quality solutions, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We offer high quality product and competitive price, welcome the regular and new customers cooperate with us!

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.