Dacron antistatic needled felt dust collector filter bag Industrial dust bag pulse filter

Product Description

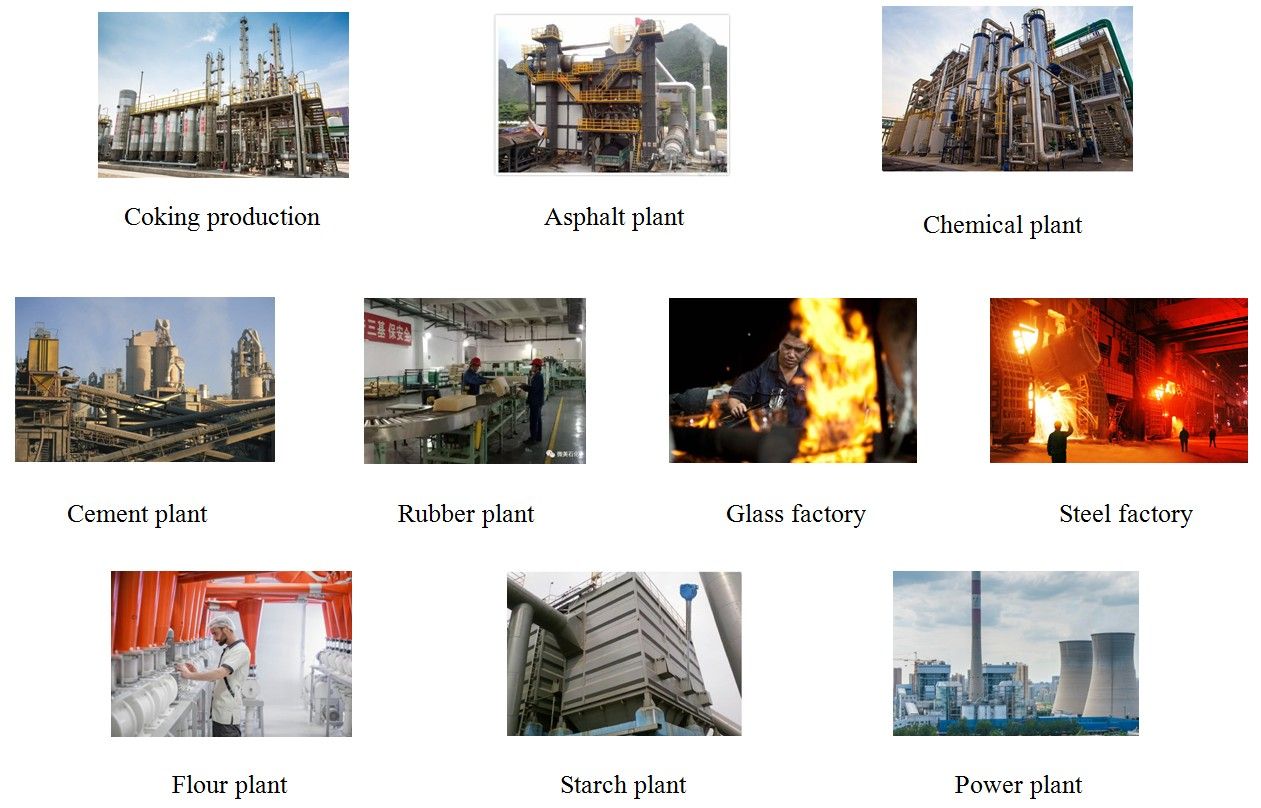

Polyester dust collector filter bag are very popular recently, most of the cement industry electrical plant asphalt plant waste water treatment workshop come to us.

Technical Parameters of Equipment Selection:

Weight: 500g/ m²

Material: Polyester/Polyester/Polyester Antistatic Substrate Thickness: 1.8mm

Permeability: 15 m³/ m²· min

Radial control force: > 800N/5 x 20cm

Latitudinal control force: > 1200N/5 x 20cm

Radial control force: <35%

Latitudinal control force: <55%

Usage temperature:≤130°C

Post-treatment: singeing, calendering, or Teflon coating

Needle Felt Cloth

Application

Packing & Shipping

Write your message here and send it to us