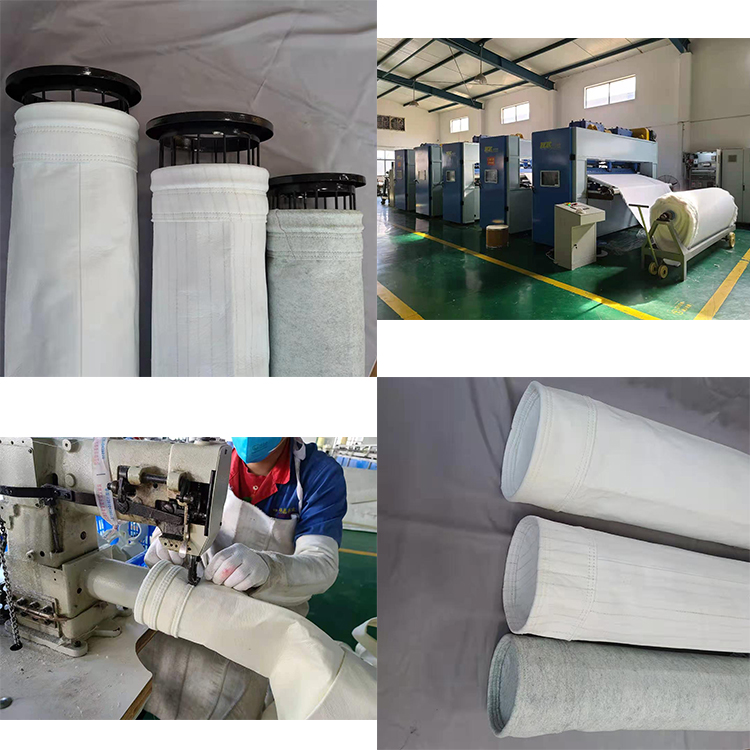

Flumex (FMS) High Temperature Resistant Needle-punched Felt Bag

Flumex dust filter bag is composed of two or more kinds of high temperature resistant fiber mixing and laminated, to achieve higher, updated physical and chemical properties. Flumex dust bag has the characteristics of high temperature resistance, high strength, acid and alkali corrosion resistance, wear resistance, bending resistance and so on. After different surface chemical treatment and finishing technology, it also has the characteristics of easy dust removal, water and oil resistance, anti-static and so on. Compared with the glass fiber dust removal filter bag, the wear resistance, flexural resistance and peeling strength are significantly improved, and it can bear high filtration load. The filtration speed can reach more than 1.0m/min, and the operation resistance is low. The product has the characteristics of high temperature resistance, high strength, acid and alkali corrosion resistance, wear resistance, bending resistance, after different surface chemical treatment and finishing technology, but also with easy to remove ash, water and oil, anti-static and other functions, and suitable for 200°C-300°C series products.

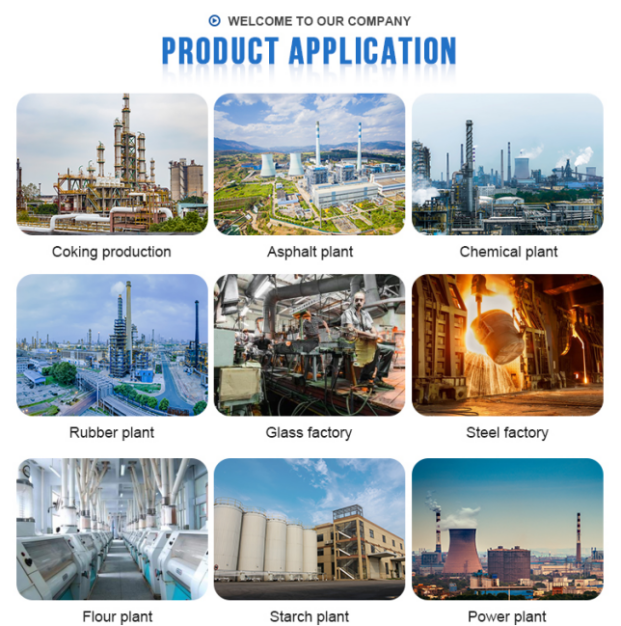

Compared with fiberglass cloth bags, its wear resistance, flexural resistance and peeling strength are obviously improved. The filtration speed can reach more than 1.0m/min and the running resistance is low. It is widely used in steel, non-ferrous smelting, chemical industry, carbon black, building materials, electric power and other industries.

Weight: 800g/ m²

Material: Aramid. fiberglass/ fiberglass substrate Thickness: 2.5mm

Permeability: 10 m³/ m²· min

Radial control force: > 2000N/5 x 20cm Latitudinal control force: > 2000N/5 x 20cm Radial control force: < I 0%

Latitudinal control force: < 10%

Usage temperature: ≤ 260°C

Post-treatment: PTEF treatment, calendering