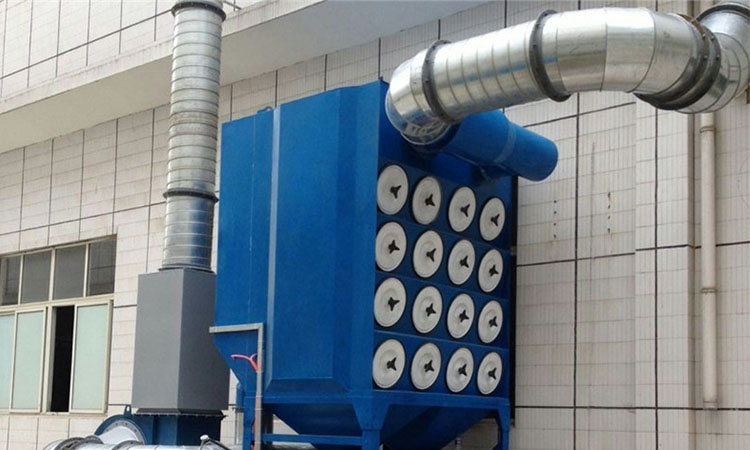

In terms of saving, using, developing and designing electric energy, protecting the ecological environment, avoiding environmental pollution, and improving working standards, filter cartridge dust collector manufacturers have achieved remarkable results in their use, ensuring long-term stable operation. Cartridge dust collectors are generally used to recycle the nicotine contained in the organic waste gas formed in the whole process of sintering in the ring furnace of carbon plants. The filter cartridge dust collector has a small size and Immediately recycle nicotine without reprocessing and building grit chambers.

Internal inspection items of electric removal of filter cartridge dust collector:

1. The internal structure of the filter cartridge dust collector cover ceramic tank is fouled, and the filter cartridge dust collector is removed in time to maintain cleanliness.

2. The nicotine adhesion condition of the corona discharge electrode wire and the sink tube, if too much nicotine on the corona wire will reduce the dust collector rate of the decoking filter cartridge of the electric capture, the corona wire should be properly handled or replaced.

3. Check whether the surface layer of the filter cartridge dust collector sinking positive tube has bulges or areas that are prone to penetrating charge and discharge, and solve them in time.

4. Check whether the gas distribution plate under the filter cartridge dust collector is blocked by nicotine, and clean it with steam.

5. Check whether the corona wire is broken, whether the heavy hammer has fallen off, and handle it properly.

6. Whether the corona discharge electrode wire of the filter cartridge dust collector is located in the core part of the deposition tube, the axial force of the corona discharge electrode wire and the bending deformation of the filter cartridge dust collector should be solved in time.

Cartridge dust collectors are generally used to purify gas in chemical plants, liquefied gas in big cities, coking, carbon plants, gas boilers, ceramic plants and other industries. Room, vertical, etc.

With the working experience of the filter cartridge dust collector in the treatment of carbon leaching flue gas, the product has developed a new type of filter cartridge dust collector and supporting facilities products. The actual effect of discharge is far less than the specification. When the imported smoke and dust are applied at 90℃-120℃, the filter cartridge dust collector gets rid of the composite insulator penetration, creepage, and electrostatic removal during the application period of the original dust removal equipment. With the reduction of the rate of the device, problems such as fire and so on.

Post time: Mar-02-2022