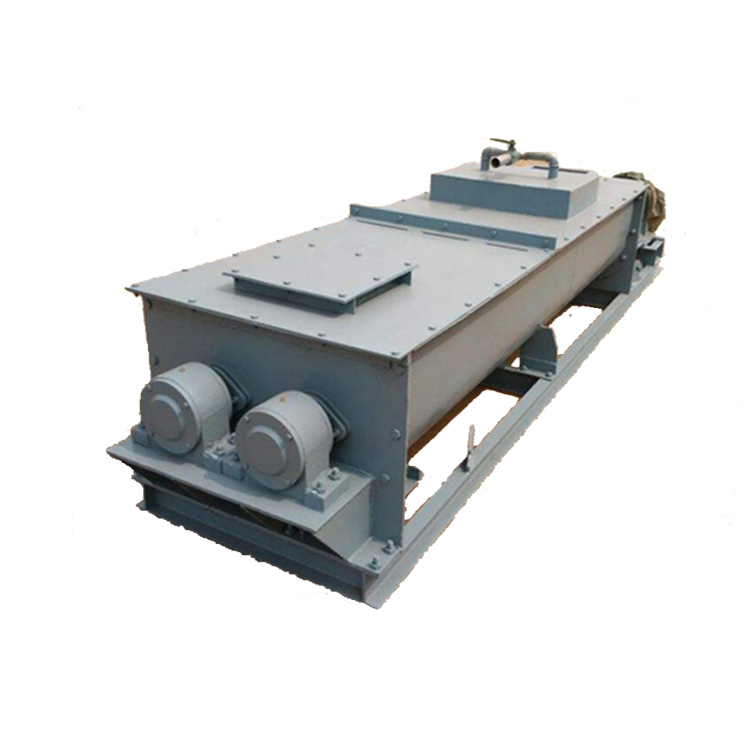

Double-Axis Dust Humidifying Mixer

SJ double-axis dust humidifier

When working, the ash and slag in the silo will be uniformly sent to the cylinder by the impeller feeder, the blade will push the ash and slag forward, and the water supply nozzle will add an appropriate amount of water to stir and force mixing. In the process of mixing, a certain gap between the cylinder wall and the stirring shaft is maintained to push the material to the discharge, which has the characteristics of compact structure, advanced technology, stable and reliable easy maintenance.

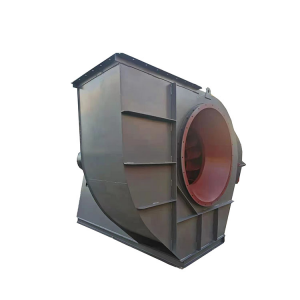

BDSZ Single Shaft Gust Humidifying Mixer

Working principle: The device as a whole on the base of cylinder is supported by four groups of elastic element, through the excitation device, to vibrate, make the machine in the process of operation, the cylinder for high frequency vibration, make wall and always keep some space between the stirring shaft, make the machine running resistance greatly decreases, and thoroughly to eliminate the boring machine, locked-rotor phenomenon, reduce downtime cleaning time, improve the working efficiency. The water supply is controlled by a group of valves. In order to stabilize the water supply and clean water quality of the system, a filter is set in the pipeline, and the main control cabinet interlocks each part of the humidifier to achieve the purpose of controlling the constant humidity operation of water supply. Stirring humidifier with large capacity, compact structure, advanced technology, stable and reliable, simple maintenance and other characteristics.

SJ double-axis dust humidifier uses two groups of spiral blades to mix, which has high mixing efficiency. The spiral blades are made of special alloy or composite ceramics with high wear resistance and long service life. It is mainly used in the dust collector of thermal power plant, and can also be used in chemical, metallurgical, mining, building materials and other industries.

BDSZ Single Shaft Gust Humidifying Mixer:

BDSZ series vibration type single shaft dust humidifier is another generation of advanced dust humidifier in our company after DS series humidifier. The vibration system is added to the original equipment, which not only has the characteristics of OS series single-axis dust humidifier, but also overcomes the problems of dust forming tube wall bonding and enhances the range of application of the humidifier

|

Uniaxial dust humidifier |

Model |

Production capacity t/h |

Main engine power kw |

Feeder power kw |

Power of vibration motor kw |

Applicable temperature °C |

Water pressure mpa |

Water content% |

|

BDSZ-50 |

15 |

7.5 |

1.1 |

0.4 |

≤300 |

≥0.2 |

15-20 |

|

|

BDSZ-60 |

30 |

11 |

1.5 |

0.75 |

≤300 |

≥0.2 |

15-20 |

|

|

BDSZ-80 |

60 |

18.5 |

1.5 |

2 |

≤300 |

≥0.2 |

15-20 |

|

|

BDSZ-100 |

100 |

37 |

2.2 |

2.5 |

≤300 |

≥0.2 |

15-20 |

|

|

BDSZ-120 |

160 |

45 |

2.2 |

3.7 |

≤300 |

≥0.2 |

15-20 |

|

|

Double-Axis dust humidifier |

Model |

Production capacity t/h |

Main engine power kw |

Helical |

Reducer Model |

Speed r.p.m. |

Water pressure mpa |

Water content% |

|

SJ-40 |

20 |

5.5 |

400 |

WXD5.5-6-43 |

34 |

0.4-0.8 |

15-20 |

|

|

SJ-50 |

40 |

7.5 |

500 |

WXD7.5-6-43 |

34 |

0.4-0.8 |

15-20 |

|

|

SJ-60 |

60 |

11 |

600 |

WXD11-6-43 |

34 |

0.4-0.8 |

15-20 |

|

|

SJ-80 |

80 |

18.5 |

800 |

WXD18.5-9-35 |

34 |

0.4-0.8 |

15-20 |

|

|

SJ-100 |

100 |

22 |

1000 |

WXD22-9-35 |

34 |

0.4-0.8 |

15-20 |