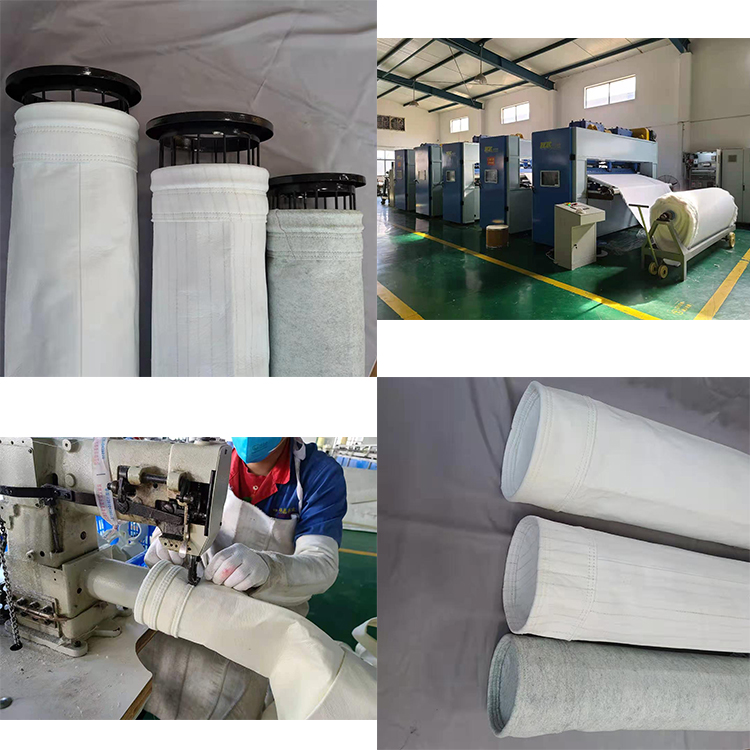

Polyester Needle-Punched Felt Bag

Its main use of synthetic fiber, from the plane, for a single fiber irregular staggered combination; Viewed from the direction of section, the needle moving at a certain Angle in the opposite plane makes the single fiber show a complex complexing state .

1, Good air permeability: compared with other fabric filter material, the biggest difference is the pore shape in the filter material.

2, High dust collection efficiency: needled felt (dust bag) single fiber complex, so that the formation of a smaller aperture than woven fabric.

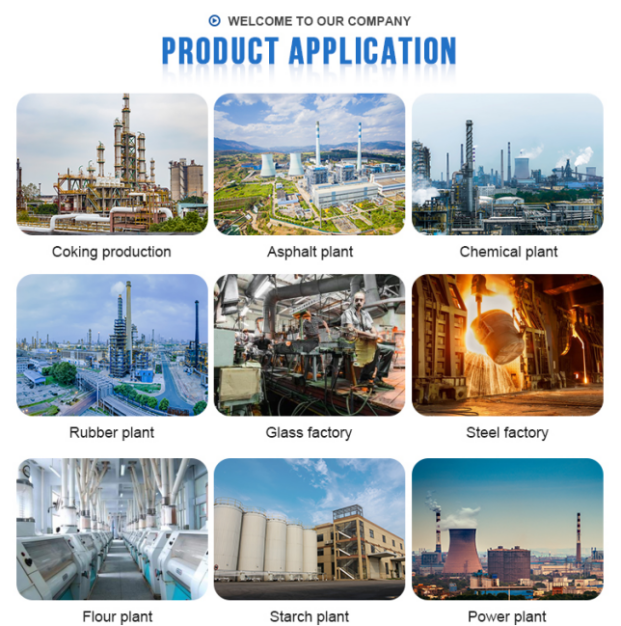

3, Suitable for high-energy dust cleaning. Therefore, it shows its excellent filtration performance and good use effect in pulse, rotary back blowing, ring gap blowing, air ring blowing and washing bag filter.

4, Needle felt filter material (dust collector bag) varieties

(1) ordinary needled felt: polypropylene, vinylon, polyester and other needled felt.

(2) Medium-temperature resistant needled felt: the working temperature of NOMEX needled felt is 200℃.

The bag has the advantages of high void, good air permeability, high dust collecting efficiency and long service life, which are peculiar to common felt filter bags. It has moderate high temperature resistance, and can reach 130"C in an instant. It also has moderate acid and alkali resistance. and very good wear resistance.

Weight: 500g/ m²

Material: Polyester/Polyester Filament Substrate Thickness: 1.75mm

Permeability: 16 m³/ m²· min

Radial control force:> 1100N/5'20cm Latitudinal control force:> 1400N/5.20cm Radial control force: <25%

Latitudinal control force: <45%

Usage temperature:.; 130°C

Post-treatment: singeing, calendering, heat selling