Concrete batching U-shaped screw feeding conveyor chute screw conveyor

Product Description

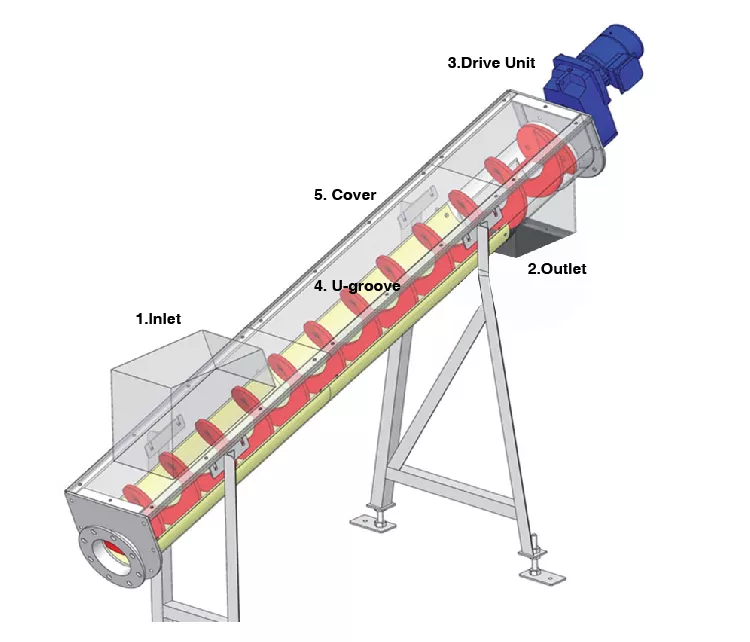

Screw conveyor is a kind of machinery that uses a motor to drive spiral rotation and push materials to achieve the purpose of conveying. It can be transported horizontally, obliquely or vertically, and has the advantages of simple structure, small cross-sectional area, good sealing, convenient operation, easy maintenance, and convenient closed transportation. Screw conveyors are divided into shaft screw conveyors and shaftless screw conveyors in the form of conveying. In appearance, they are divided into U-shaped screw conveyors and tubular screw conveyors. Shaft screw conveyors are suitable for non-viscous dry powder materials and small particle materials (for example: cement, fly ash, lime, grain, etc.), while shaftless screw conveyors are suitable for conveyors with viscous and easy-to-wind materials. (For example: sludge, biomass, garbage, etc.) The working principle of the screw conveyor is that the rotating screw blade pushes the material to be conveyed by the screw conveyor. The force that prevents the material from rotating with the screw conveyor blade is the weight of the material itself. The frictional resistance of the screw conveyor casing to the material. The spiral blades welded on the rotating shaft of the screw conveyor have solid surface, belt surface, blade surface and other types according to the different materials to be conveyed. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to give the axial reaction force of the screw with the material. When the length of the machine is long, an intermediate suspension bearing should be added.

Product advantages of U screw conveyor:

1. Installation and disassembly do not need axial movement, long mandrel, less hanging, and fewer failure points

2. Adopt a variable diameter structure to increase the volume of the hanging bearing

3. Within the range, it can freely rotate with the conveying resistance to avoid material jams or blockages

4. The head and tail bearing seats are all outside the shell, with long service life

5. Good sealing performance, stable and reliable operation, multi-point loading and unloading and operation in the middle.

Packaging and shipping