Dust Feeder Valve Screw Conveyor For Dust Collector

Product Description

Screw conveyor series screw conveyor is divided into horizontal screw conveyor and vertical screw conveyor from the angle of displacement direction of conveying materials. It is mainly used for horizontal conveying and vertical lifting of various loose materials, such as powder, granular and small pieces. It is not suitable for conveying deteriorative, viscous, caking or high temperature, pressure-resistant and relatively high. Special materials with high corrosiveness. Screw conveyor is widely used in various industries, such as building materials, chemical industry, power, metallurgy, coal mine, grain and other industries.

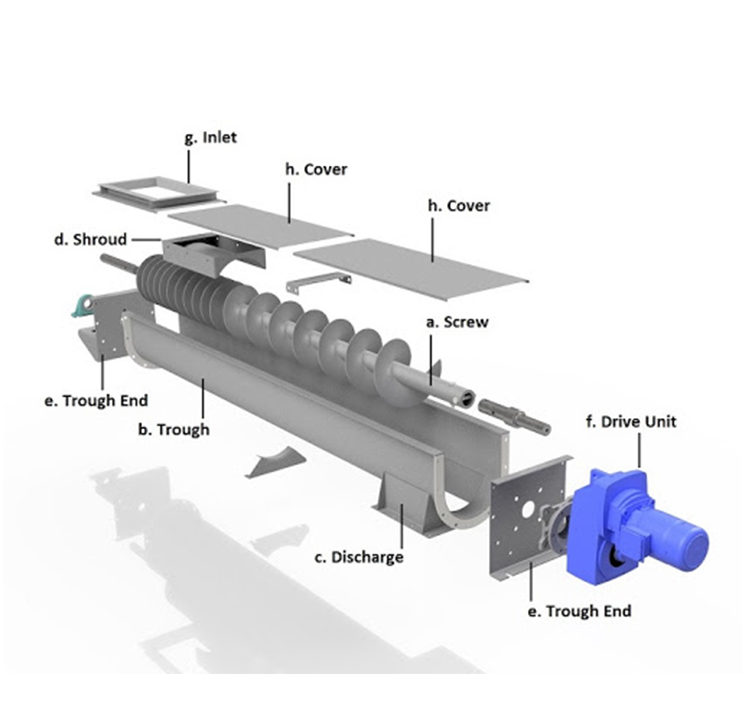

Structure and working principle:

The equipment adopts a shaftless screw type. When the material enters from the feed hopper of the conveying press, it relies on the rotation of the screw blades to push the material to the compaction zone along the U-shaped conveying groove. Under the reverse spring pressure, the grid slag is squeezed and dehydrated. The dewatered grid slag is forced to open the pressure plate and fall to the garbage trolley for transportation. The squeezed seepage water flows into the grid well through the return pipe.

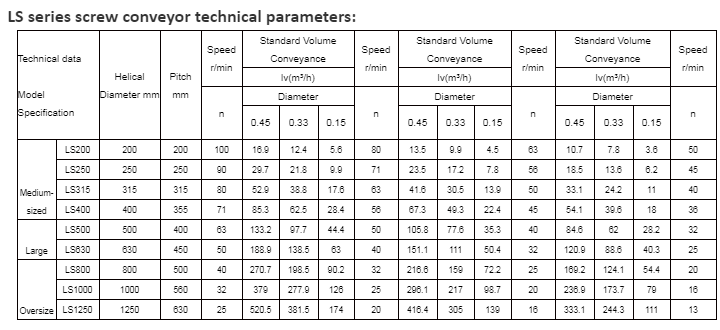

LS series screw conveyor technical parameters:

| Technical data

Model |

Helical Diameter mm |

Pitch |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

Standard Volume Conveyance |

Speed r/min |

|||||||

|

lv(m³/h) |

lv(m³/h) |

lv(m³/h) |

||||||||||||||

|

n |

Diameter |

n |

Diameter |

n |

Diameter |

n |

||||||||||

|

0.45 |

0.33 |

0.15 |

0.45 |

0.33 |

0.15 |

0.45 |

0.33 |

0.15 |

||||||||

|

Medium-sized |

LS200 |

200 |

200 |

100 |

16.9 |

12.4 |

5.6 |

80 |

13.5 |

9.9 |

4.5 |

63 |

10.7 |

7.8 |

3.6 |

50 |

|

LS250 |

250 |

250 |

90 |

29.7 |

21.8 |

9.9 |

71 |

23.5 |

17.2 |

7.8 |

56 |

18.5 |

13.6 |

6.2 |

45 |

|

|

LS315 |

315 |

315 |

80 |

52.9 |

38.8 |

17.6 |

63 |

41.6 |

30.5 |

13.9 |

50 |

33.1 |

24.2 |

11 |

40 |

|

|

LS400 |

400 |

355 |

71 |

85.3 |

62.5 |

28.4 |

56 |

67.3 |

49.3 |

22.4 |

45 |

54.1 |

39.6 |

18 |

36 |

|

|

Large |

LS500 |

500 |

400 |

63 |

133.2 |

97.7 |

44.4 |

50 |

105.8 |

77.6 |

35.3 |

40 |

84.6 |

62 |

28.2 |

32 |

|

LS630 |

630 |

450 |

50 |

188.9 |

138.5 |

63 |

40 |

151.1 |

111 |

50.4 |

32 |

120.9 |

88.6 |

40.3 |

25 |

|

|

Oversize |

LS800 |

800 |

500 |

40 |

270.7 |

198.5 |

90.2 |

32 |

216.6 |

159 |

72.2 |

25 |

169.2 |

124.1 |

54.4 |

20 |

|

LS1000 |

1000 |

560 |

32 |

379 |

277.9 |

126 |

25 |

296.1 |

217 |

98.7 |

20 |

236.9 |

173.7 |

79 |

16 |

|

|

LS1250 |

1250 |

630 |

25 |

520.5 |

381.5 |

174 |

20 |

416.4 |

305 |

139 |

16 |

333.1 |

244.3 |

111 |

13 |

|

Application

Screw conveyors are widely used in various sectors of the national economy such as the food industry, building materials industry, chemical industry, machinery manufacturing industry, and transportation industry. Screw conveyors are mainly used for conveying various powder, granular and small block materials. The bulk materials conveyed include grains, beans, flour and other grain products, cement, clay, sand and other building materials, salts, and alkalis. , Chemical fertilizers and other chemicals, as well as bulk bulk cargoes such as coal, coke and ore. Screw conveyors are not suitable for conveying materials that are perishable, viscous, large in size, and easily agglomerated. In addition to transporting bulk materials, screw conveyors can also be used to transport various finished items. The screw conveyor can complete mixing, stirring, cooling and other operations while conveying materials. In ports, screw conveyors are mainly used for unloading trucks, ship unloading operations, and horizontal and vertical transportation of bulk materials in warehouses. The screw unloader, which uses the horizontal screw shaft in direct contact with the material to unload the material layer by layer from both sides of the carriage, has been successfully used in domestic ports for many years. The screw ship unloader composed of horizontal screw conveyor, vertical screw conveyor and relative screw reclaiming device has become a more advanced continuous ship unloading model, which is increasingly widely used in domestic and foreign bulk cargo docks.